China and India are the first and second largest bamboo producers in the world. But while Chinese bamboo exports contribute 65% to the international market, Indian exports account for less than 1% of the global market.

Meanwhile, the global bamboo market is projected toreach $ 88.44 Bn by 2030, growing at a CAGR of 4.7% from 2025 to 2030. So the opportunity for Indian bamboo farmers is pretty large.

This disparity dawned on Amwoodo cofounder Agni Mitra in Sweden when he saw almost all bamboo products in a supermarket were made in China. For someone from Kolkata, where bamboo grows in abundance, that sight sparked a question that wouldn’t go away: why wasn’t India making these products?

“China dominates because its machines are designed for its own species, Moso bamboo. Indian species like Tunda and Balcooa didn’t suit those machines. So, we started manufacturing our own machines compatible with Indian bamboo species,” Amwoodo cofounder Mitra told Inc42.

The startup began operations in 2019, with the aim of selling Indian bamboo products across Europe, but realised that it needed to first complete a mission at home—building a local bamboo economy from the ground up.

After navigating COVID disruptions, training farmers across the northeast, and setting up a factory in Kolkata, the once‑flickering idea had grown into a sustainable platform, providing alternatives to single-use plastics.

The brand’s name also carries an interesting story. In Mitra’s words, “When I was in Germany, one of my lab mates was a Mauritanian guy named Mamadou. He told me that in their tribal language, Amwoodo means ‘I am sustainable.’ He suggested the name for the venture—I thought, why don’t I continue this name when I set up an environment-conscious company in India.”

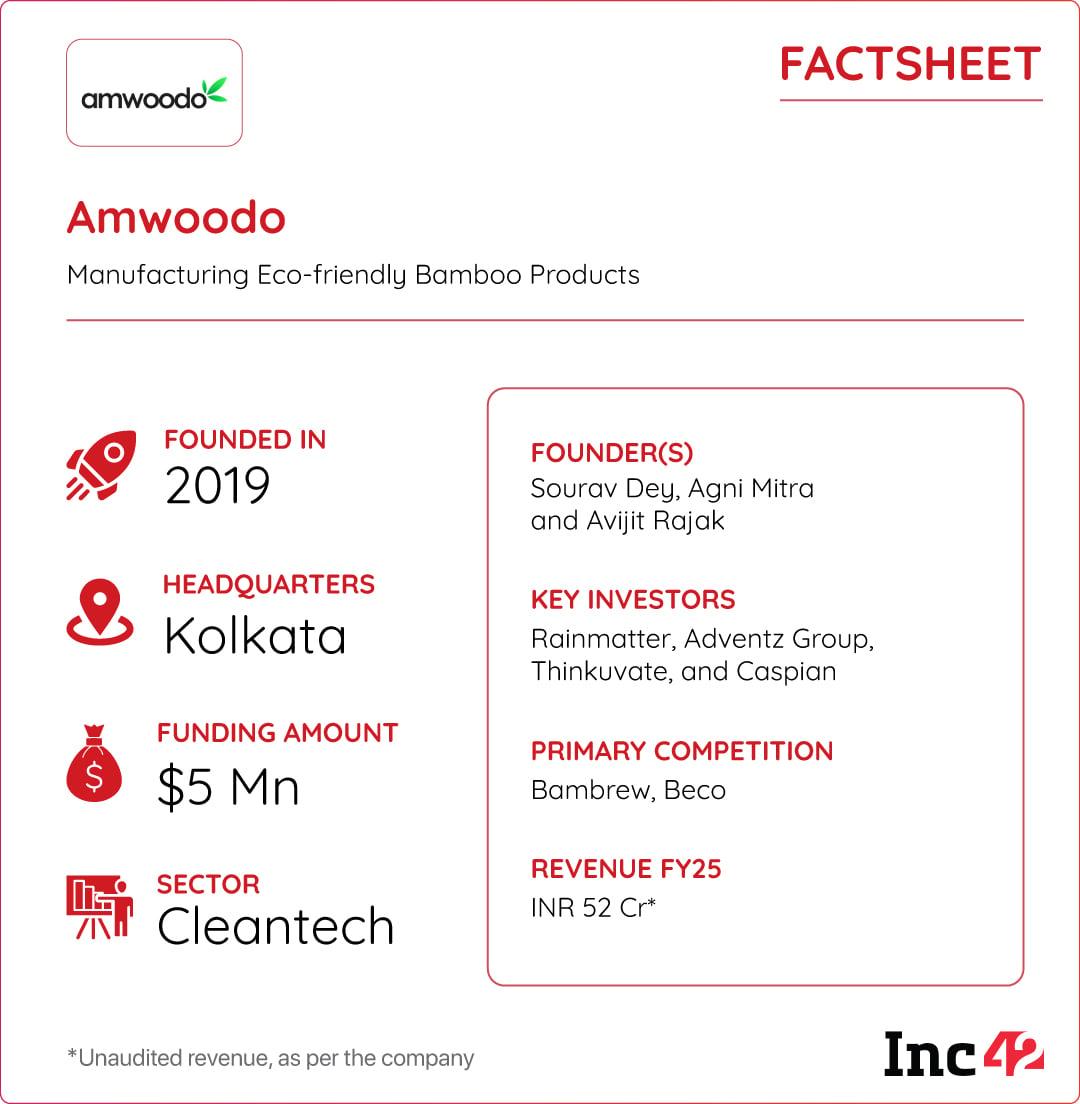

From Bamboo Farmlands To Everyday EssentialsAmwoodo was founded by three first-time entrepreneurs — Mitra, Sourav Dey, and Avijit Rajak — who neither had a business background nor family fortunes to set up the business.

According to Mitra, it was a shared conviction to build something meaningful that compelled the trio to start their own business. “It was a humble beginning for all of us,” recalls Mitra. “In fact, I had to personally convince Sourav’s family to let him join, because as Bengalis, they preferred stable jobs over risky ventures.”

Before founding Amwoodo, Mitra worked with companies like Infosys, Medtronic, and Olympus, primarily in the medical devices sector. His career took him around 60 countries for nearly eight years— experiences that shaped his worldview.

“The idea for Amwoodo itself came while traveling. I was inspired by global innovations — not to imitate them, but to adapt them to India’s realities.”

India’s growing plastic pollution problem caught Mitra’s attention. He observed that people were not serious enough about waste segregation or legacy waste, and felt that instead of focusing solely on managing waste, it would be more effective to prevent it by creating biodegradable, eco-friendly alternatives that generate less waste in the first place.

That thought set the foundation for Amwoodo. He saw immense potential in bamboo — a fast-growing, renewable material with applications ranging from tissues and toothbrushes to furniture and even building materials.

The global bamboo market size was estimated at$ 67.13 Bn in 2024, but Mitra believes the opportunity is far greater.

However, when he returned to India, he found most farmers and artisans were unaware of bamboo’s versatility. It was still seen mainly as a craft or décor material — beautiful but not scalable. Meanwhile, China dominated the global bamboo market because its machinery was optimised for its native Moso bamboo. Indian species like Tunda and Balcooa, however, didn’t suit those machines.

That gap became Amwoodo’s breakthrough. “We started designing and manufacturing our own machines, tailored for Indian bamboo species,” Mitra explains. The team built a sustainable supply chain, sourcing bamboo directly from Indian farmers and training artisans to process it efficiently. This not only reduced waste but also created livelihoods.

The venture began with just four farmers and three artisans. Initially, Amwoodo focused on supplying machinery and equipment to Farmer Producer Organizations (FPOs) and Artisan Producer Organizations (APOs).

In the early days, the team’s biggest challenge was the lack of trained manpower. Since the bamboo industry was still in its infancy, they had to train workers entirely from scratch. The business was also capital-intensive, and being bootstrapped until 2023, they depended heavily on bank loans for funding.

To secure working capital, the cofounders even went as far as mortgaging their own homes.

Now, with banks like NABARD, SBI, and Bank of Baroda funding the sector, the company shifted its focus toward strengthening its own factories and research and development.

Today, bamboo is primarily procured from Assam, Tripura, Odisha, Jharkhand, and West Bengal. Amwoodo claims to have developed a “micro-factory” model, where farmers and artisans carry out primary processing near their homes or farms.

The final processing happens at Amwoodo’s main factories in Dankuni and Rajarhat in West Bengal. From there, eco-friendly bamboo products make their way across India and beyond.

Amwoodo’s journey began as a pure business-to-business (B2B) venture, with a focus on hospitality and contract manufacturing. The company supplied sustainable dry amenities such as bamboo toothbrushes, combs, and razors to some of India’s largest hotel chains, including Taj, Hilton, and ITC, as well as to personal care brands like Kimirica.

It also manufactured eco-friendly products for consumer brands such as Himalaya, Bombay Shaving Company, The Man Company, and The Souled Store.

The real breakthrough came in 2022, when Taj Hotels (IHCL) became one of the first major hospitality groups to commit to sustainability following the government’s single-use plastic ban. Once Taj switched to bamboo-based alternatives, other hotel chains quickly followed suit.

Building these partnerships wasn’t easy for Amwoodo. The team reached out directly to procurement heads through LinkedIn and cold calls, relying on transparency and trust to open doors. Potential clients were invited to visit Amwoodo’s factory and witness the entire production process firsthand—a move that often converted curiosity into confidence.

“Amwoodo’s farmer-and-artisan impact stories became a key differentiator, helping partner companies strengthen their ESG (Environmental, Social, and Governance) compliance credentials,” said Mitra.

While bamboo products remain slightly more expensive—about 5–10% higher than plastic alternatives—the cost gap has narrowed significantly as production scaled. With its fast growth cycle and sustainable yield, bamboo proved both economically and environmentally viable.

As the company scaled its B2B operations, Amwoodo also began diversifying into direct-to-consumer (D2C) and business-to-government (B2G) segments.

On the D2C front, the startup sells bamboo-based lifestyle and home products such as tissues, bottles, cutlery, and kitchen towels across 18 online marketplaces, including Amazon, Flipkart, Zepto, and Blinkit.

Amwoodo currently claims to generate around INR 1.5 Cr per month from direct sales and expects to close the year FY26 with about INR 20 Cr in annual revenue from this channel.

Under its D2C umbrella, Amwoodo operates three in-house brands—ImeCo, ShaveCo, and Dencrus—all housed under its sustainable marketplace, Ecoconscious.

- Imeco: ImeCo focuses on everyday lifestyle essentials like tissues, bottles, and cutlery

- ShaveCo: ShaveCo offers sustainable shaving products

- Dencrus: Dencrus is dedicated to oral care

The company is also preparing to launch two new brands—Good Habit, which will cater to the HoReCa (Hotel, Restaurant, and Café) segment with eco-friendly tissues and napkins, and Conscious Story, a brand centered on sustainable gifting.

“We’re also launching Good Habit for tissues and napkins, especially for HoReCa and Conscious Story for sustainable gifting,” said Mitra.

Most D2C orders come through marketplaces and quick-commerce platforms, as the average order value of products like toothbrushes (INR 120 for a 4-pack) suits such platforms better, he added.

Among these, Blinkit has emerged as a top performer, especially in Kolkata, Bengaluru, Mumbai, and Delhi.

“We’re also working with Treebo and similar chains. Budget hotels are more price-sensitive, so we’re introducing bundled kits to match plastic-kit pricing. For instance, we replaced conventional toothpaste tubes with sachets or tablets—these cost INR 2–3 less per kit, helping balance overall pricing,” said Mitra.

The startup has deployed 5-6 machines per FPO level and APO level. The startup is currently working with 17 FPOs and 11 APOs.

Meanwhile, the setup cost of machinery and equipment at the FPO and APO level ranges between INR 5–8 Lakh, with these units capable of generating monthly revenues of INR 1–2 Lakh. At the factory level, the investment requirement increases to INR 1–3 Cr, depending on the scale of production and capacity, said Mitra.

Additionally, the company is also engaged in green building initiatives with the Steel Authority of India (SAIL) and the West Bengal government under its B2G vertical. “B2G is somewhere we are really focusing on the building materials. So flooring, cladding, then ceiling, then outside cladding, outside flooring,” Mitra added.

Balancing Scale And Environment SustainabilityThe platform that started with just four farmers and three artisans has now grown into a thriving network of over 1,500 people, including 700 farmers and 700 artisans spread across Northeast India, West Bengal, and Jharkhand.

The startup identified farmers who showed leadership potential, who were GST-compliant, ambitious, and eager to learn and trained them to become “master farmers.”

These individuals now oversee networks of smaller farmers, creating a structured, self-sustaining ecosystem. The same approach was extended to artisans. Amwoodo trained them not only in bamboo craftsmanship but also in financial literacy and leadership, enabling them to eventually run small units of their own.

“The same model worked for artisans—we trained them in financial literacy and leadership. Now, we have over 700 farmers and 700 artisans across the Northeast, West Bengal, and Jharkhand—over 1,500 people in total,” said Mitra.

The impact on livelihoods has been transformative. Farmers earnings have seen a growth over the years as they currently earn around INR 50-55K per month and artisans INR 30-35K, as claimed by the company. These figures could not be independently verified.

“In 2019, farmers were earning around INR 10–12K a month; today, many make INR 50–55K,” says Mitra. “Artisans who once earned INR 8K now take home INR 30–35K, and some master artisans earn up to INR 2–2.5 Lakh per month in profits.”

While there are no direct subsidies for bamboo-based factories, farmers benefit from government initiatives like the National Bamboo Mission, which provides support such as affordable seedlings.

Certain states, including Assam, are also developing dedicated bamboo parks — and Amwoodo is currently in discussions to set up a plant there. However, training local communities to operate specialised machinery remains an ongoing challenge.

The Growth SpurtThe turning point for Amwoodo came in 2023 when it secured a $1 Mn commitment from Rainmatter, Zerodha’s investment arm.

Amwoodo claims that its revenue climbed from INR 22 crore in FY23–24 to INR 52 crore in FY24–25, with projections of INR 100–103 Cr for the current financial year. The startup claims to remain EBITDA and PAT positive, with its core focus firmly on creating livelihoods and fostering sustainable ecosystems.

Today, around 90% of its revenue still comes from B2B, while D2C and B2G contribute the rest, Mitra said.

The startup has expanded its global footprint to the United Arab Emirates, Canada, United Kingdom, Germany, Slovakia and Singapore. “We are also exploring APAC, USA and Malaysia,” said Mitra. Last year, its exports contributed 15% to the startup’s revenue.

In September 2025, Amwoodo raised $4 million in a pre-Series A round led by its existing investor Rainmatter, alongside new backers Adventz Group, Thinkuvate, and Caspian.

The startup is looking to use fresh capital in scaling production capacity to meet surging domestic and international demand, strengthen its D2C marketplace Ecoconscious, and launch new plastic-alternative brands as it expands its footprint in the global sustainability space.

“With the fundraise, we are setting up a factory in Karnataka for processing building materials. So now we will be going big in the segment and will be supplying building materials to the major realtors and the government sectors and infra sectors,” said Mitra.

The post How Is Amwoodo Taking Indian Bamboo To Global Markets appeared first on Inc42 Media.

You may also like

Walton Goggins signed to star in 'Painter'

If you don't quit smoking in time, your thinking and understanding will rapidly decline in old age.

Biryani war in Bihar: AIMIM nomination feast descends into chaos

Man gets life imprisonment for murdering woman

My wife, children sustained burn injuries": Resident after massive fire broke out at Delhi's Brahmaputra Apartments